Speed & Accuracy of Ordering Supplies

How much time have you spent talking about replenishing supplies during this pandemic?! From toilet paper to PPE to critical raw materials, we have all learned the value of the right inventory at the right time with an efficient process to replenish. As we adjust to this ‘new normal’ AND prepare for ramping back up our operations let’s explore buying and replenishing inventory.

Speed and accuracy of ordering supplies is always beneficial. Today, during ramp up it is CRITICAL.

One of our customers had this gap. The average time to place an order was 93 minutes. Across the organization more than seven different methods were used to place an order, ranging from excel spreadsheets to the 1991 ½ page triplicate supply ordering form. An extensive amount of time was spent managing the organization’s orders. Some orders required researching an exact item, locating the best price, finding a vendor, and determining delivery times. Some orders required unnecessary approvals before the order was placed. Finally, the orderer did not always know if there were adequate funds to cover the cost; confirming with the accounting team consumed more time and delays.

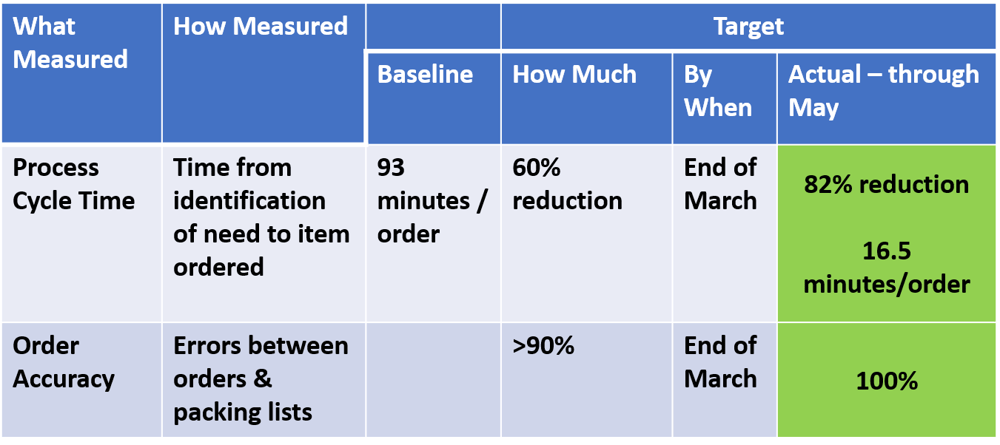

Getting better – A cross-organization team was convened to create innovation solutions and significant benefits. The table below shows the improvement in ordering time 93 minutes to 17 minutes per order. This is part of their success. Thousands of $s were saved inventorying what is needed (no more, no less) and hours and hours of more productive time. Additionally, team members had what they needed to perform their job.

They achieved these benefits quickly. How? By creating the new and eliminating the old.

- Re-sequenced and redesigned the process to eliminate unnecessary steps, recycle loops, wait times, and other wastes.

- Created job aids including 1 standard order form, a standard vendor list (by category), and a list of items than cannot be ordered. Created a share point site to access the order form and store all ordering documents.

- Shredded non-preferred vendor catalogs.

- Distributed P-cards to heavy orderers.

- Provided budget and codes, by role.

- Granted orderers access to vendor web sites.

- Trained team members in the new standard work procedure.

Going beyond the Ordering process the team helped improve supply Receiving, Inventory Management, and Replenishment.

- Created delivery location rules.

- 5S'd the storage room.

- Established a kanban ordering system to decrease inventory and standardize ordering. (More on kanbans in this webinar. )

As you and your organization begin ramp up efforts let’s learn from this supply ordering and replenishment improvement team. The strategies listed here can enable your supply ordering process now and during the ramp up.

We have worked in these processes and have helped many organization quickly create innovative improvements to Ordering, Inventory Management, and Replenishment processes. Please check out your order quantities, safety stock levels, and reorder points at work and at home. Adjusting these are critical to keeping your operations flowing and managing costs. Shockingly – hording is not the answer!