Flow - Balanced Work - and Kanbans

Chris Bujak • May 3, 2021

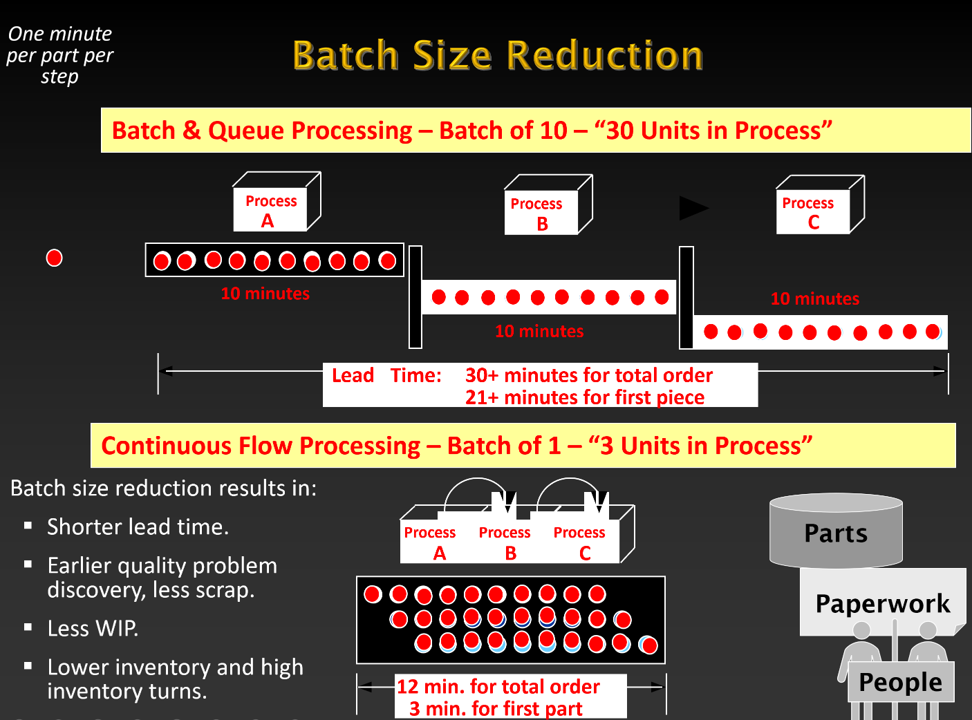

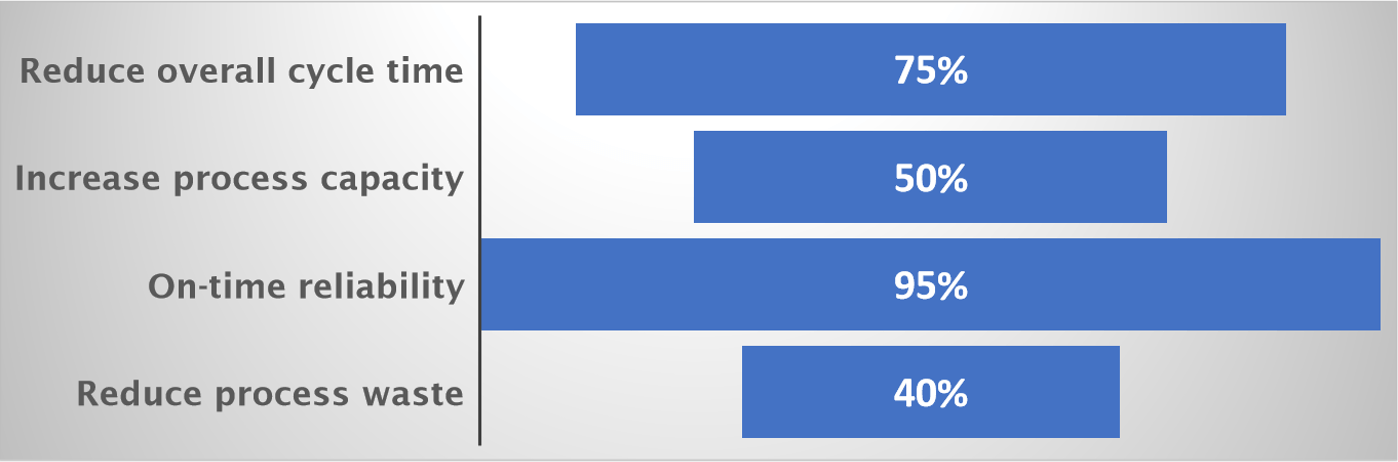

Accelerate the speed and improve the quality of a process by eliminating wait times, queue times, and other delays. Significant process improvement can be achieved with the application of flowing one unit at a time (or minimum batch size), with formulated and balanced resource responsibilities and time expectations, and kanbans (visual or automated controls) to manage and signal stop/start of items or information. These methods are best applied to processes with long cycle times, handoffs of work with long wait times, bottlenecks, and poor quality output.

Goal:

To increase knowledge and skills of the Flow, Balanced Work, and Kanban processes and methods and be able to use it to lead a team through realizing signficant time and quality improvements.

Benefits:

- Shorter lead time.

- Happier team members and customers!

- Earlier quality problem discovery

- Less scrap and rework.

- Lower total inventory and higher inventory turns.

Agenda:

Training: 40 hours of education and immediate application. Participants bring a scenario to class on which to focus and practice.

Application and Coaching: On-site event co-lead. One-on-one coaching until results are achieved.

Certification: Participation in this course and completion of 1 project = Continuous Improvement Flow Black Belt CERTIFICATION.

- Understanding the Flow methods.

- Gathering data and information.

- Determining current process variation to balance resource work load.

- Understanding and implementing kanbans.

- Understanding and implementing visual controls.

- Designing the process flow.

- Testing the work process flow and crating sticky implementation of flow, balanced work, kanbans, and visual controls.