High Performing Continual Improvement: What Benefits Can Be Achieved?

In the last article , we talked about what is keeping you up at night in your organization and the goal of continual improvement in helping to close those gaps. Let’s talk now about the type and size of benefits continual improvement can bring…

Different models of improvement place different emphasis on WHO are the recipients of the benefits and WHAT are those benefits. [1]. The benefits provided by continual improvement need to be real and inclusive of all stakeholders. Stakeholders = a person or group of people who affects or is affected by a change. Stakeholders and benefits include:

Although the list may not be surprising, there are two important points- 1) Customers hold a special and primary status (they are why you exist) and 2) Benefits to one stakeholder are not at the expense of another. [2] For example, if you use improvement methods to drive cost reduction solely for the purposes of improving the company’s profits, is that consistent with the purpose of maximizing value to customers? Does it help in worker participation in continuous improvement activities when people realize they are assisting in ending their jobs?

Are the Benefits Significant?

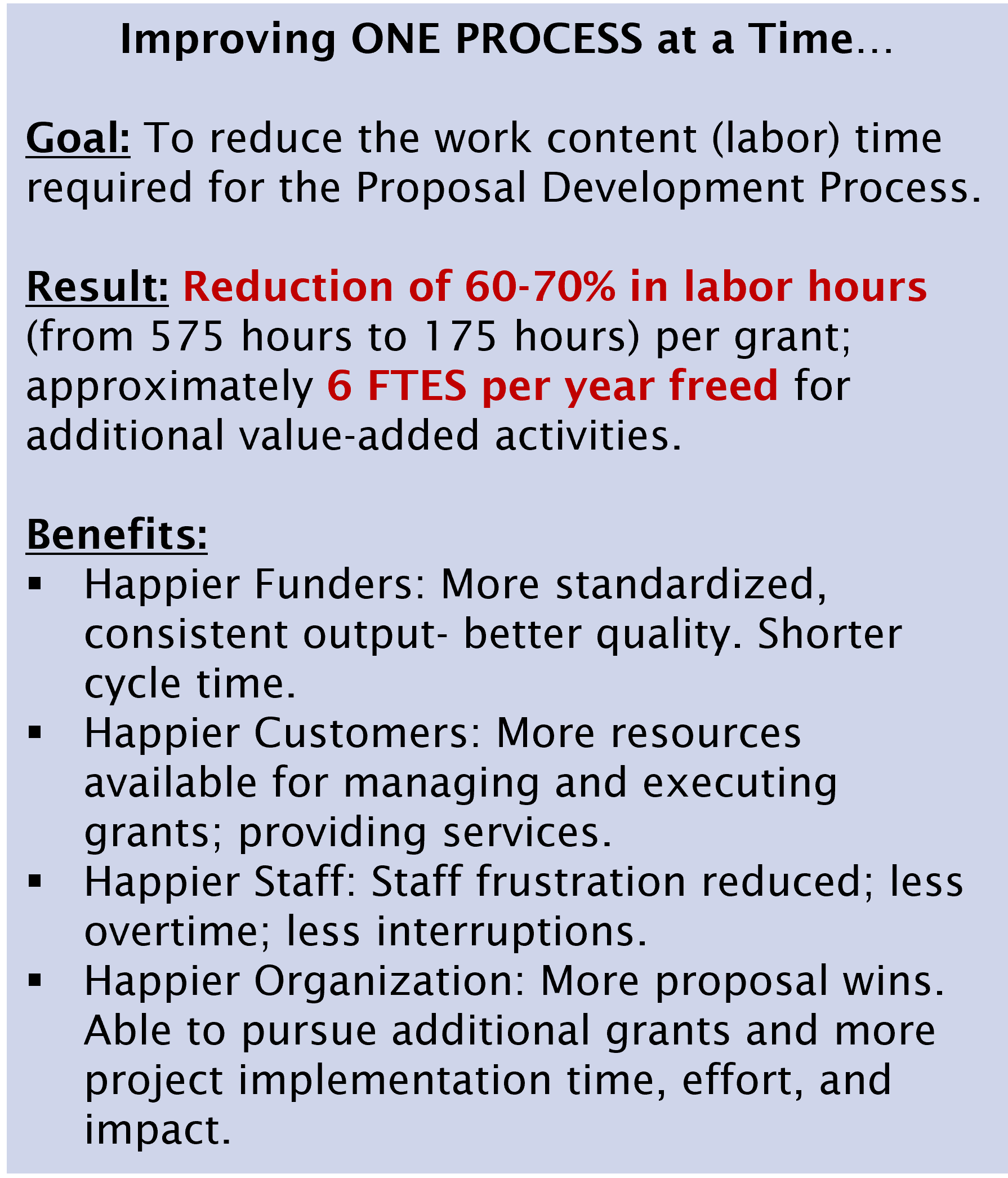

The impact of such an approach can be stunning. Organization effectiveness and efficiency can be increased at a rate greater than historical norms and perhaps greater than thought possible. Outcomes for customers can be improved. Costs can be improved that allow for more customers to be served with the same number of staff. Time can also be freed up to pursue other value-added activities.

Some Examples:

Customer: The time to deliver products and their quality are often of paramount importance to customers. Applying Flow [3] and Mistake Proofing to processes has produced cycle time reduction and defect reductions of 60-75!

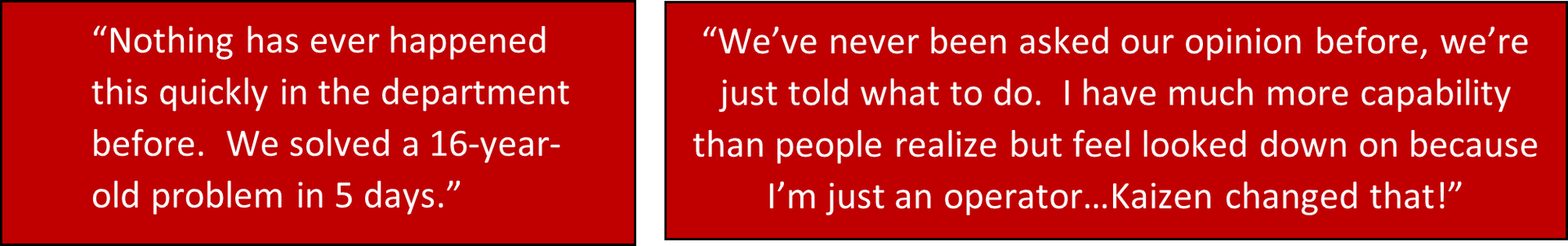

Team Members: Team members have the opportunity to influence their process, make it less frustrating, grow in their personal capacity, experience a sense of ownership and, yes, have some fun!

Organization:

- Work processes throughout the organization are impeded by wastes such as searching, waiting, and defects. Eliminating the wastes can reduce costs, increase profit, increase capacity with the same resources and free up labor for other value adding activities. Applying Kaizen [5] often produces a 20-50% reduction in work process labor content!

- Reducing inventory often provides significant financial and operational benefits (reducing the cost of carrying the inventory, increasing cash flow, increasing floor space to support growth) and can be done in a manner that reduces runouts. Applying Flow, producing to customer demand and applying replenishment techniques can reduce inventory 40-60% and significantly increase cash flow from operations (see case history below)!

Suppliers: Often organizations teach their suppliers improvement and collaborate on improving processes across organizations. As a result, suppliers experience some of the same benefits as your organzation!

Community: Benefits are created by

a. a direct impact from safe and well-paying jobs provided by the organization

b. an indirect impact if the organization buys production materials and services locally

c.

an induced impact from the flow of wages spent by new employees.

If you would like some help in calculating the amount of opportunity in your organization, give us a call!

Putting it Together

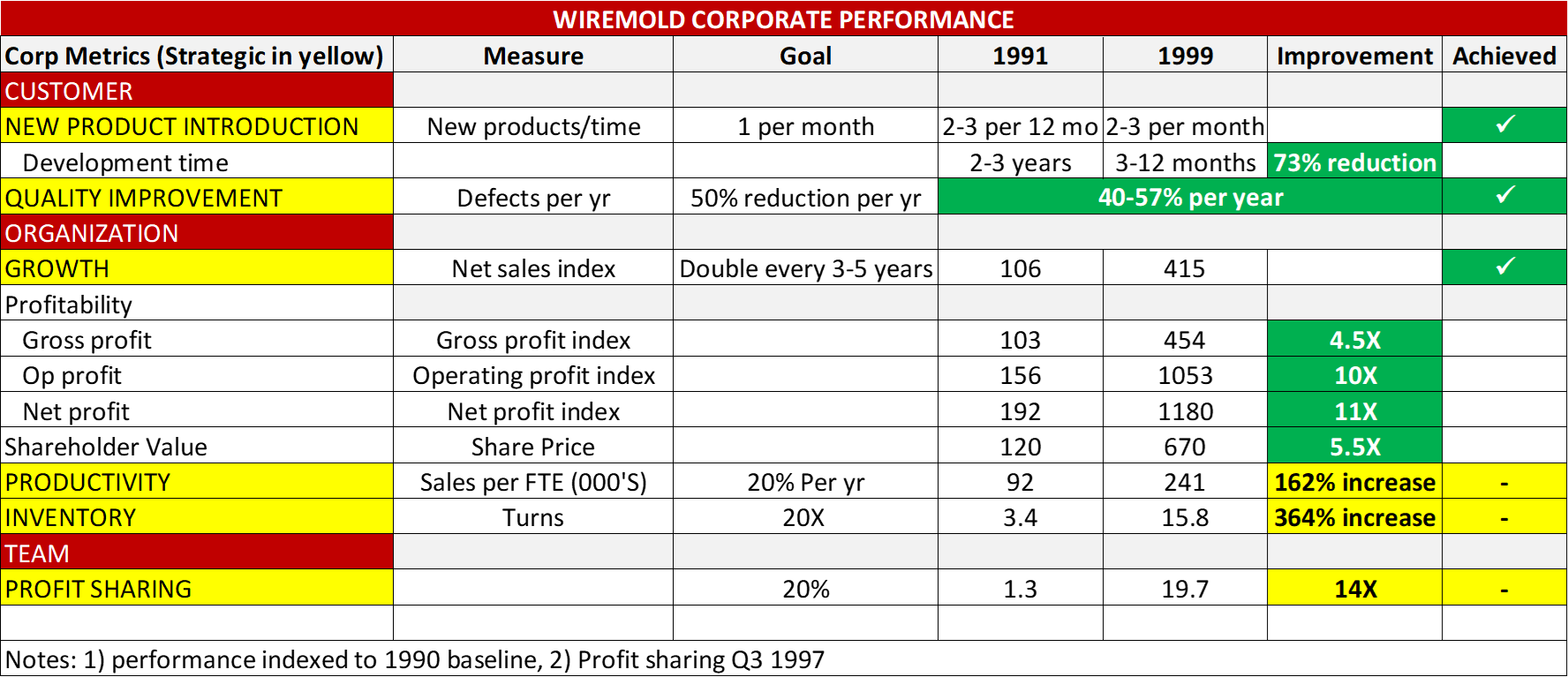

One of the companies examined for a transformation to a culture of continual improvement during the period of 1991 to 1999 was The Wiremold Company [6] , a manufacturer of wire and cable management products. Their CEO, Art Byrne, is credited for leading their transformation by establishing a corporate-wide, core strategy of continual improvement to remove waste and improve value-adding activities in order to deliver more value to their customers. Their results were impressive- significant increases in growth, new products, speed, quality, productivity, profitability and benefit sharing with the team. And, they freed up cash from inventory reduction to partially fund their acquisitions!

What is the secret sauce?

Actually, the basics are no secret. Art and the Wiremold team during this time exemplified many of the key elements of high performing improvement by

- Establishing continual improvement as a key strategy,

- Role modelling key values and behaviors,

- Engaging their team members,

- Focusing the organization on high priority opportunities,

- Applying the information and data based methods of improvement such as kaizen in work processes throughout the organization,

- and continually learning.

[1]

See “Lean or “L.A.M.E.”” (Lean As Misguidedly Executed), Graban

[2] See Emiliani, 2004, “Zero Sum Thinking”

[3] Flow: A method that attacks wait time between process steps by reducing batch size, balancing work content and visually controls activity

[4] Mistake Proofing: A method to reduce human error by making it more difficult or impossible to make an error

[5] A team-based method using a systematic process to identify waste in the targeted work process, understand and analyze the root causes, identify and test solutions, extract learning, install improvements, and create a system for ongoing improvement; accomplished in typically 5 days

[6] To read the rest of the story, read Better Thinking, Better Results”, Emiliani