Total Productive Maintenance (TPM)

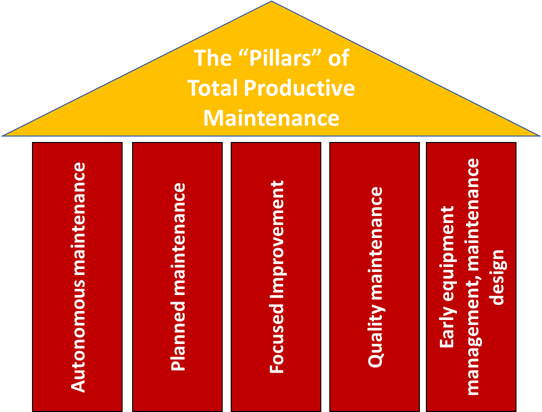

Learn how to help teams get involved in creating/improving maintenance operations and processes resulting in equipment reliability, less labor, and more capacity! This education includes 5 strategies (pillars) to proactively apply preventative maintenance processes to maximize the operational efficiency of equipment.

Goal of Total Productive Maintenance (TPM):

To increase TPM pillar knowledge, skills, and ability to use TPM to create more team productivity, safety, and equipment effectiveness.

Benefits:

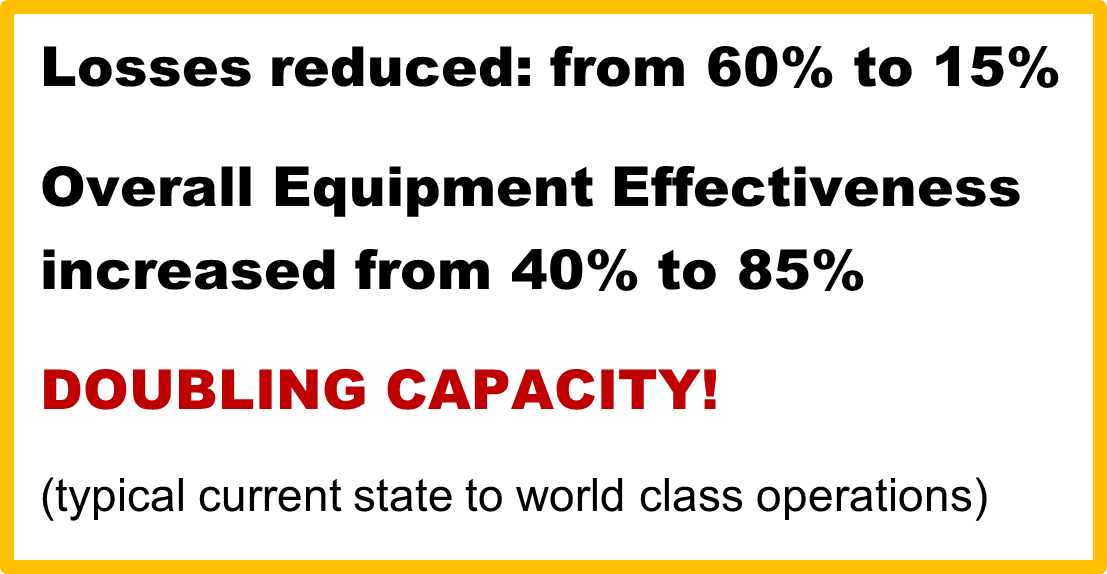

- Reduce the “Six Big Losses” of equipment utilization (unplanned outages, brief stops, running at low rate, production defects, reduced yield, and setup).

- Improve equipment effectiveness, productivity, capacity, and safety, and continue progress to a culture of improvement.

- Build teamwork, ownership and understanding in the equipment management and understanding of the equipment capabilities.

Agenda:

Training: 7 days of education and application.

Training in the WHAT, WHY and HOW of TPM, including its concepts, losses that are addressed, strategies (“pillars”) that are used to make improvement, measures of performance, a roadmap for implementation and a project template to guide success. Participants bring a scenario to class on which to focus and practice.

Module 1: 3 days classroom training

- Understanding the what, why, and how of Total Productive Maintenance

- Chartering the effort and creating the case for change

- Measuring (baseline, target, and trending progress)

- Building the TPM team

- Communicating the case for change

- Applying details of TPM Pillars and the roadmap to establish: Autonomous maintenance

- Application (one month)

Module 2: 2 days classroom training

- Applying details of TPM Pillars and the roadmap to establish: Focused improvement

- Applying details of TPM Pillars and the roadmap to establish: Planned maintenance

- Application (one month)

Module 3: 2 days classroom training

- Applying details of TPM Pillars and the roadmap to establish: Quality maintenance

- Applying details of TPM Pillars and the roadmap to establish: Early equipment management / maintenance design

Application and Coaching: One-on-one coaching until results are achieved.

Certification: Participation in this course and completion of 1 project = Continuous Improvement TPM Black Belt