Mistake Proofing (aka Poka Yoke)

Creating a high-performing work environment where human errors and defects are not accepted. Instead errors and defects are identified, and work processes redesigned to control, minimize, or ELIMINATE the occurrence and effects of human error. This course will help develop knowledge and skills to effectively and efficiently facilitate the systematic Mistake Proofing approach to prevent defects associated with “human error” and avoid the costs resulting from those defects.

Goal of Mistake Proofing:

- Develop the knowledge and skills to understand and use the systematic mistake proofing approach.

- Decrease defects associated with “human error” and avoid the costs resulting from those defects.

Benefits:

- Reduce "things gone wrong' and 'inspection' wastes.

- Changes or mistake proofing devices decrease or eliminate recurring problems.

- Immediate return on training investment.

- Knowledge and skills to continue eliminating recurring problems.

- Team engagement in seeing problems and knowing how to 'mistake proof' them away.

Agenda:

Training: 16 hours of education. Participants bring a repeating defect, problem, or a process that has lots of rework.

- Types of errors vs. defects and conditions that allow.

- The Mistake Proofing approach.

- Understand human factors and their impact.

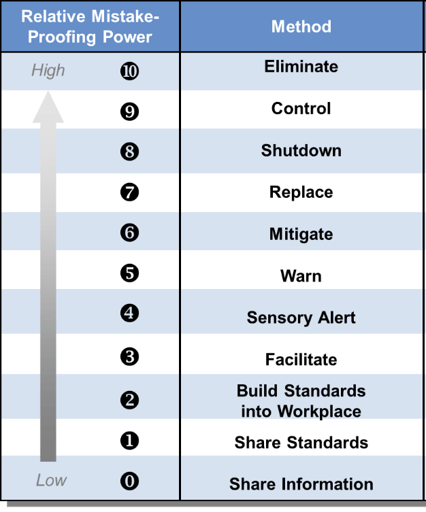

- Poka Yoke devices and strategies.

Application: During the education, apply the mistake proofing process and idenitfy device(s) to decrease/eliminate defects and create some immediate benefit.

Requisite: CI White Belt. Yellow Belt training recommended.

Coaching: On-site personal coaching & help provided by Continual Impact during training and application.

Certification: Participation in this course and implementation of >=1 improvement/change/device = Continuous Improvement Mistake Proofing Belt CERTIFICATION.