Blog Layout

Quick Change - SMED

Chris Bujak • Apr 30, 2021

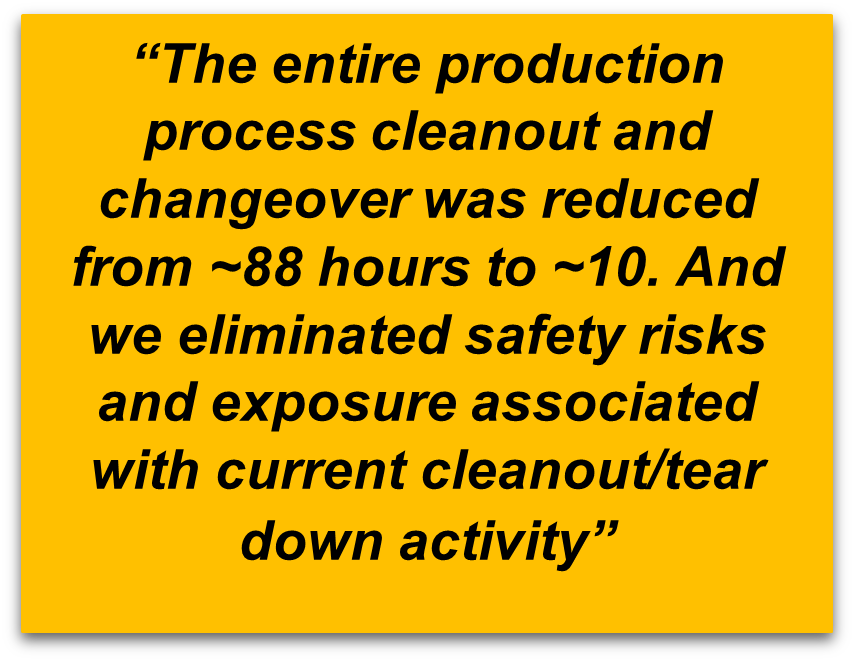

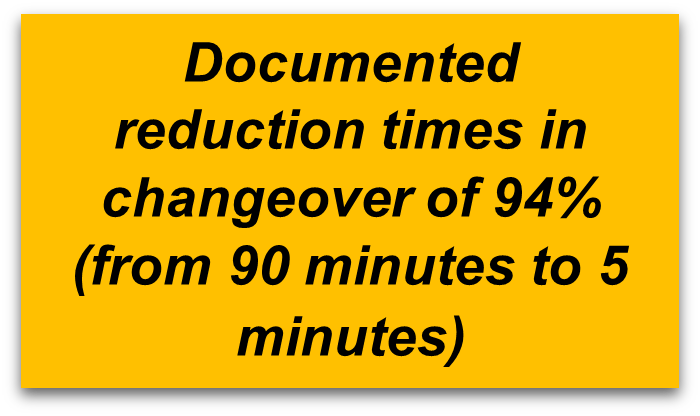

SMED (single minute exchange of dies) improvements reduce the waste of getting ready to do work. Reductions in changeover times of equipment or processes create immediate and significant benefits in labor productivity, cycle time and inventory. The SMED approach assesses each task of a changeover process to distinguish what can be done externally to the process of changeover and what cannot. The entire work process is then redesigned to eliminate tasks, move external ones out of the changeover process and streamline all remaining activities.

Goal of Quick Change - SMED:

To develop your knowledge and skills to effectively and efficiently facilitate the improvement cycle within a SMED event including confirming and preparing the scope and team; performing the SMED event; and implementing the improvements.

Benefits:

- Decreased process to process change over times.

- Increased productivity.

- Increased capacity.

- More process flexibility.

- Payback typically within 1 month-1 year.

- Team pride and ownership, as well as more energy and enthusiasm for more improvement.

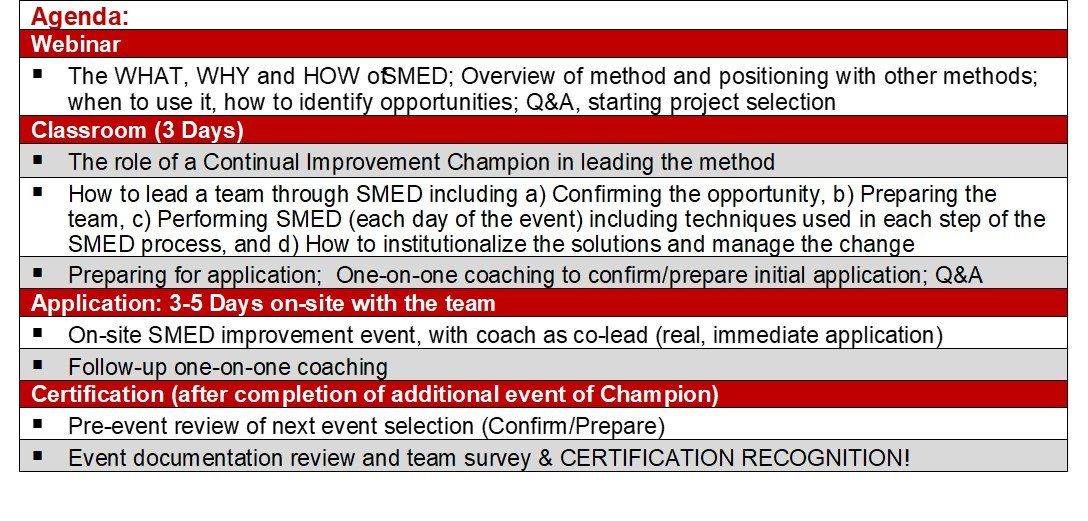

Agenda:

Training: 24 hours of education and immediate application. Participants bring a scenario to class on which to focus and practice.

Application and Coaching: 4-5 days of on-site event co-lead. One-on-one coaching until results are achieved.

Certification: Participation in this course and completion of 1 project = Continuous Improvement SMED Black Belt CERTIFICATION.