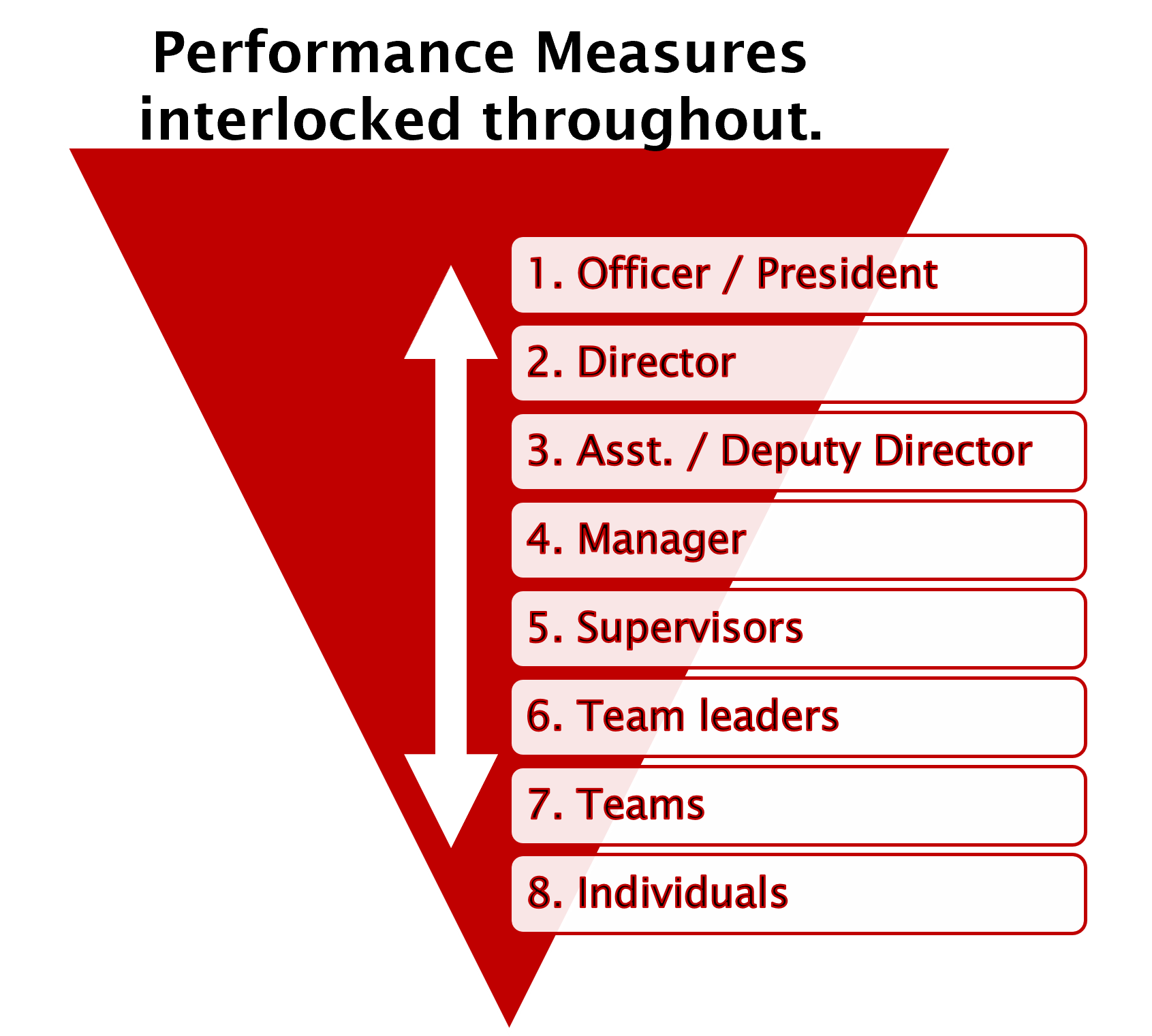

Role-Based Training Courses

Select a

Role

to See Related Courses

(see full list below)

All Courses

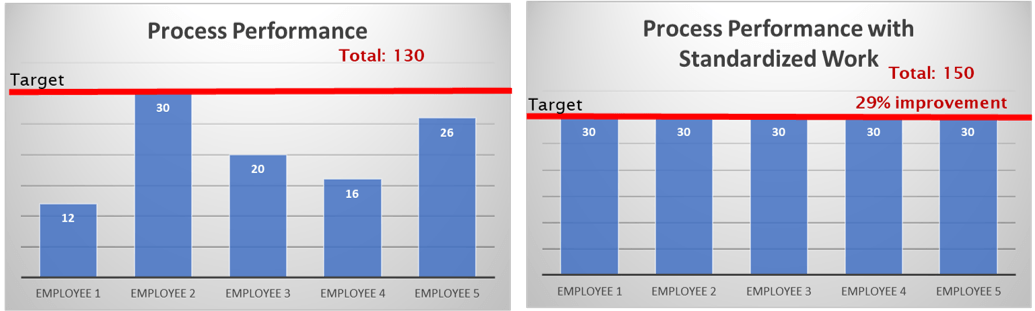

Getting results is key!

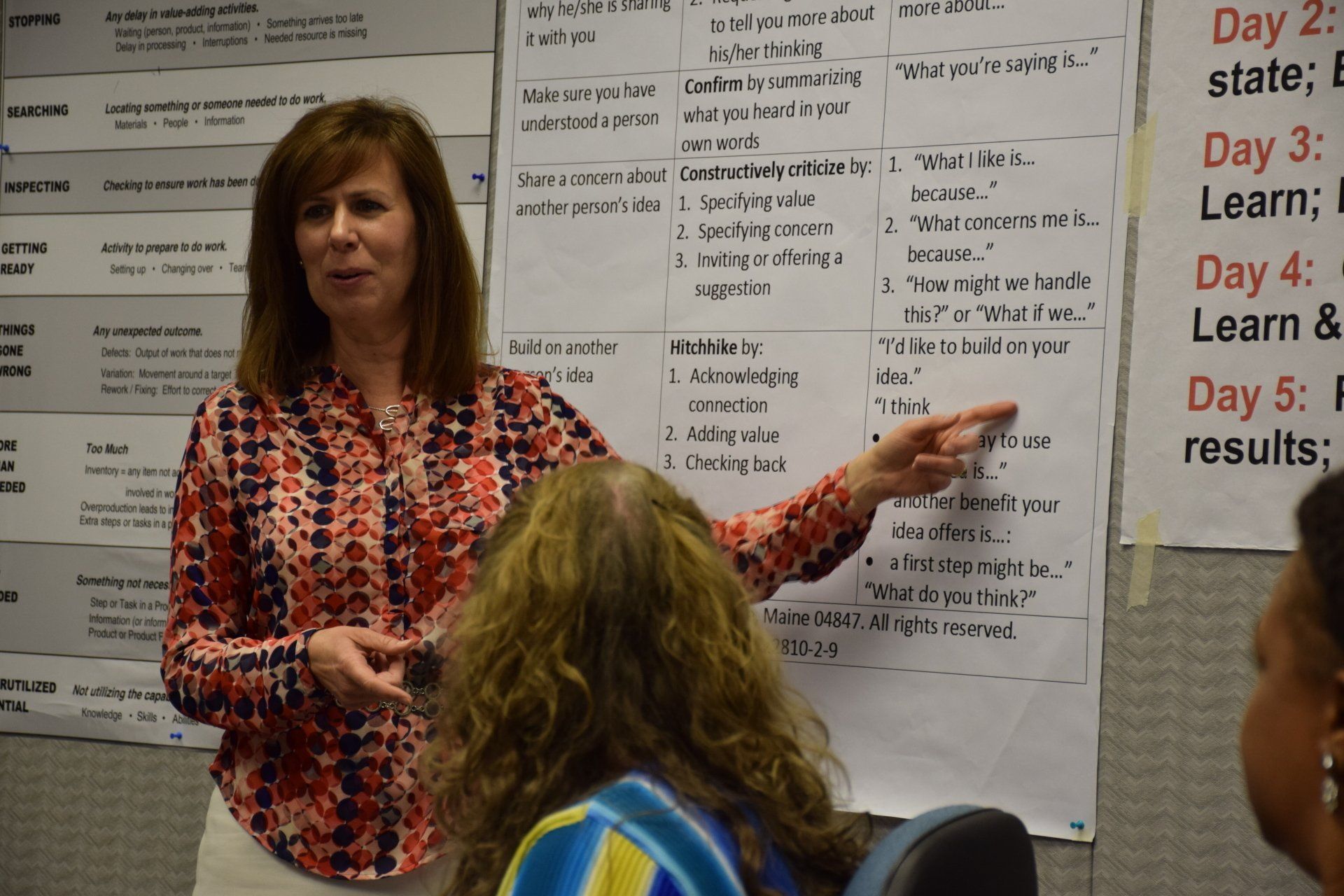

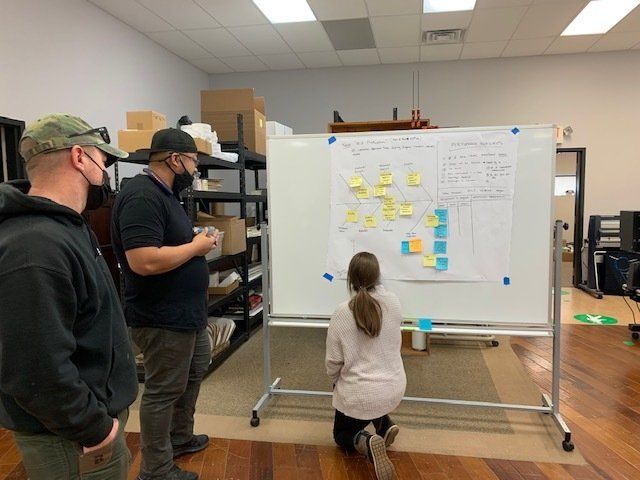

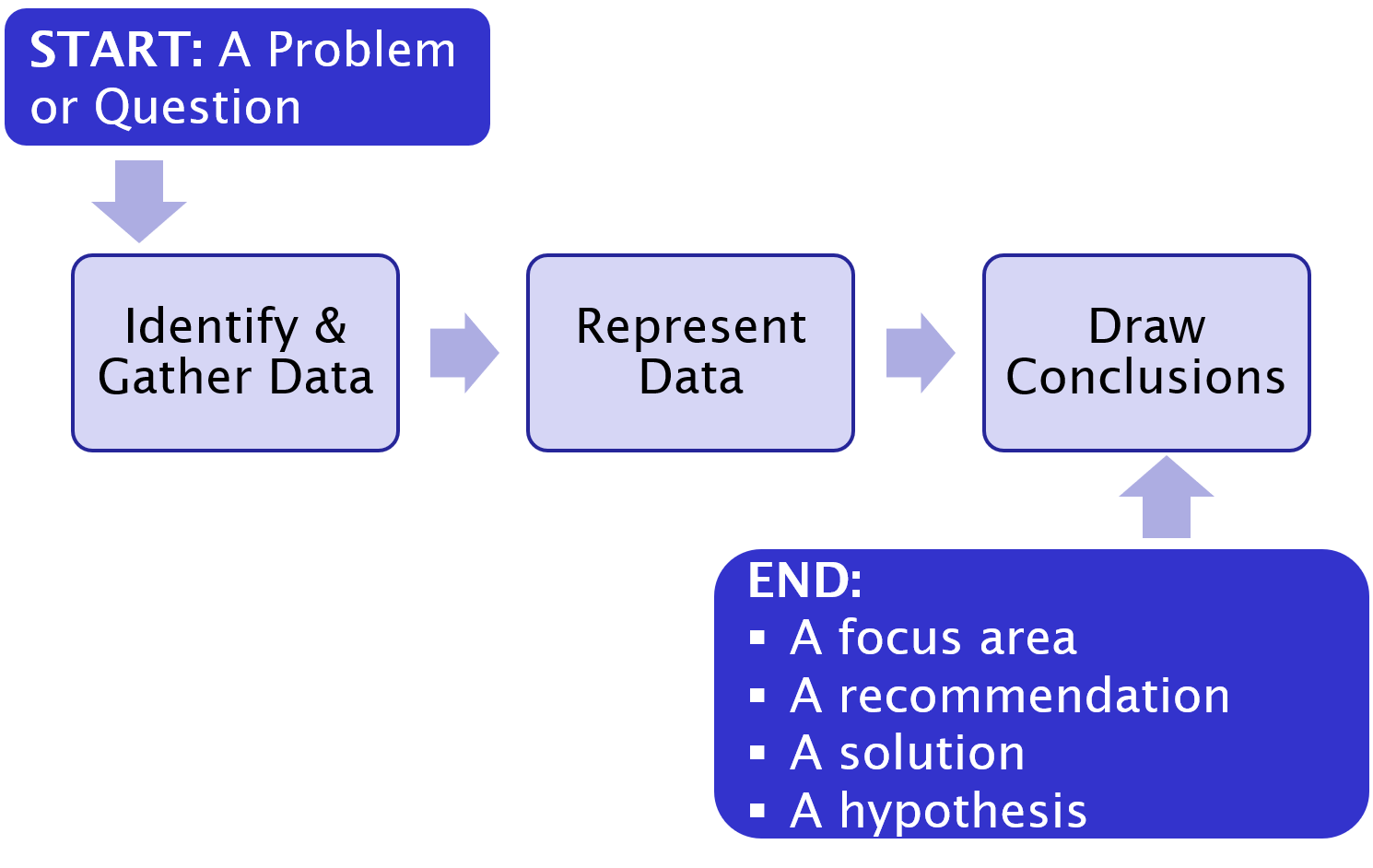

All training includes education and knowledge transfer. We rely significantly on the adult education principles of TELL, SHOW, DO, RECYCLE (provide feedback). Application, in the classroom and in the real world, are keys to knowledge transfer and results.

"Thank you and your team for the outstanding training yesterday (Std. Oper. Proc. & Processing Mapping). I truly enjoyed the session. I feel that this training will benefit the entire agency. With an upcoming retirement, it's a great tool to prepare the department and new team members to fall into place without any major hiccups. Please, extend this training to all staff."

"I very much enjoyed and appreciated the tools I learned in this course - I know I will find this process useful throughout the rest of my career. Thank you for taking the time to work with me, and for the constructive feedback."

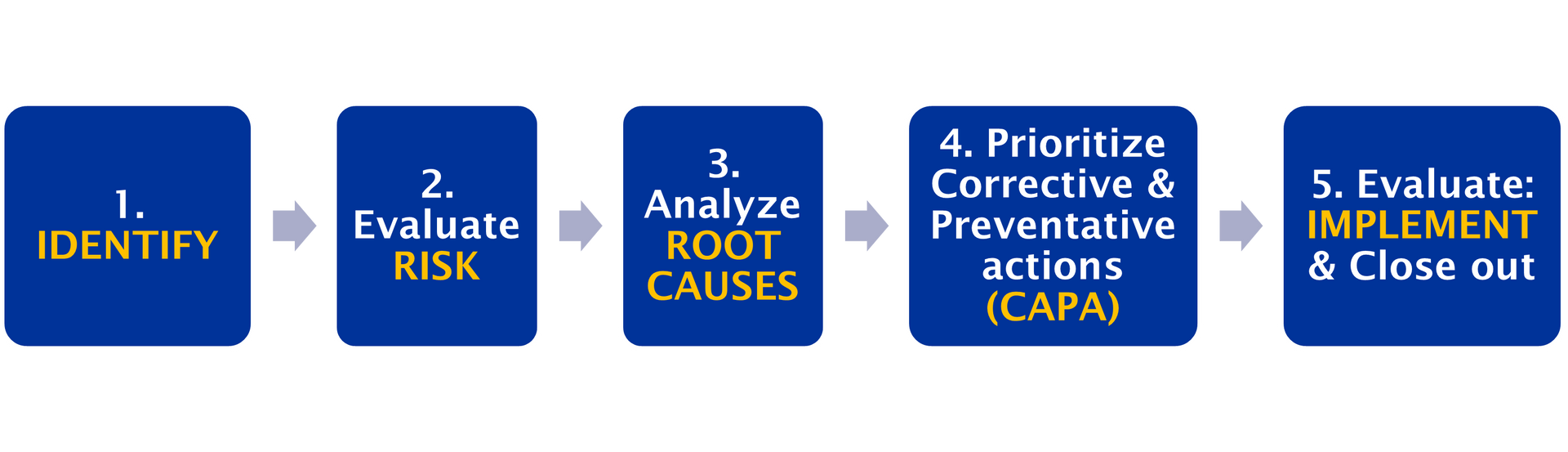

"Thanks for the feedback! I’m excited with this whole process! The other day I worked with my daughter on process mapping and root cause on why she can’t seem to keep her room clean. We actually identified some really good changes, and it has been SO much better!! Less stress for everyone. It’s so cool seeing the process work so well. THANK YOU!!"

"My Yellow Belt Project is done! I appreciate the class and this process because it forced me to look at a project in a different and more complete way than I did in the past. Thanks for everything!?